Manufacturing

We have the in-house capabilities and expertise to handle any OEM volume requirement.

No Order Is Too Big

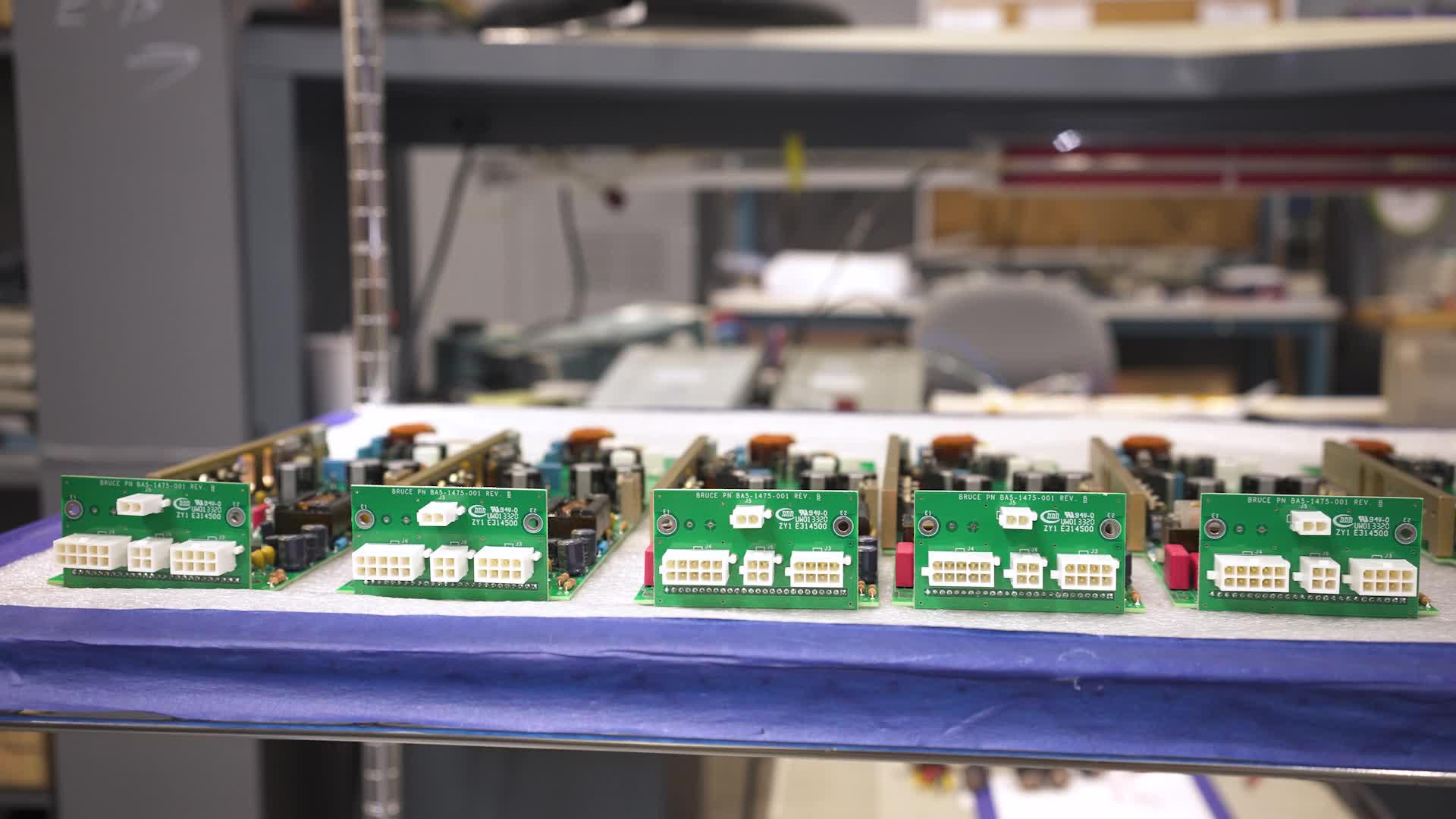

Bruce Aerospace offers comprehensive manufacturing capabilities, including in-house PCB production with state-of-the-art Surface Mount Technology (SMT) and automated thru-hole soldering for high-density, efficient assembly. Our advanced metal forming capabilities, featuring 3-Axis CNC machines and sheet metal cutting/forming, allow for seamless prototyping and full-scale production. We also excel in plastic forming with injection molding, vacuum forming, and 3-D printing, enabling the creation of custom plastic parts. Our wiring and harnessing services include complete wire harness assembly and testing, ensuring quick and efficient integration. Additionally, our in-house painting and printing processes provide custom artwork and color matching services.

All products are assembled and rigorously tested at our Carson City, NV facility, ensuring they meet the highest performance and safety standards. With a 90,000 square foot state-of-the-art facility, Bruce Aerospace is equipped to handle everything from retrofits to OEM builds, delivering high-quality, reliable products tailored to our clients' needs.

With a legacy of excellence and a commitment to quality, we are a trusted name in the industry, offering comprehensive manufacturing capabilities that cater to the diverse needs of our clients.No matter how large your need is, we can handle it. We have a state of the art 90,000 square foot facility that can handle everything from retrofits to OEM builds.

PCB Production

Metal Forming

Plastic Forming

Wiring and Harnessing

Painting and Printing