Aircraft Certification

Utilize Our Expertise

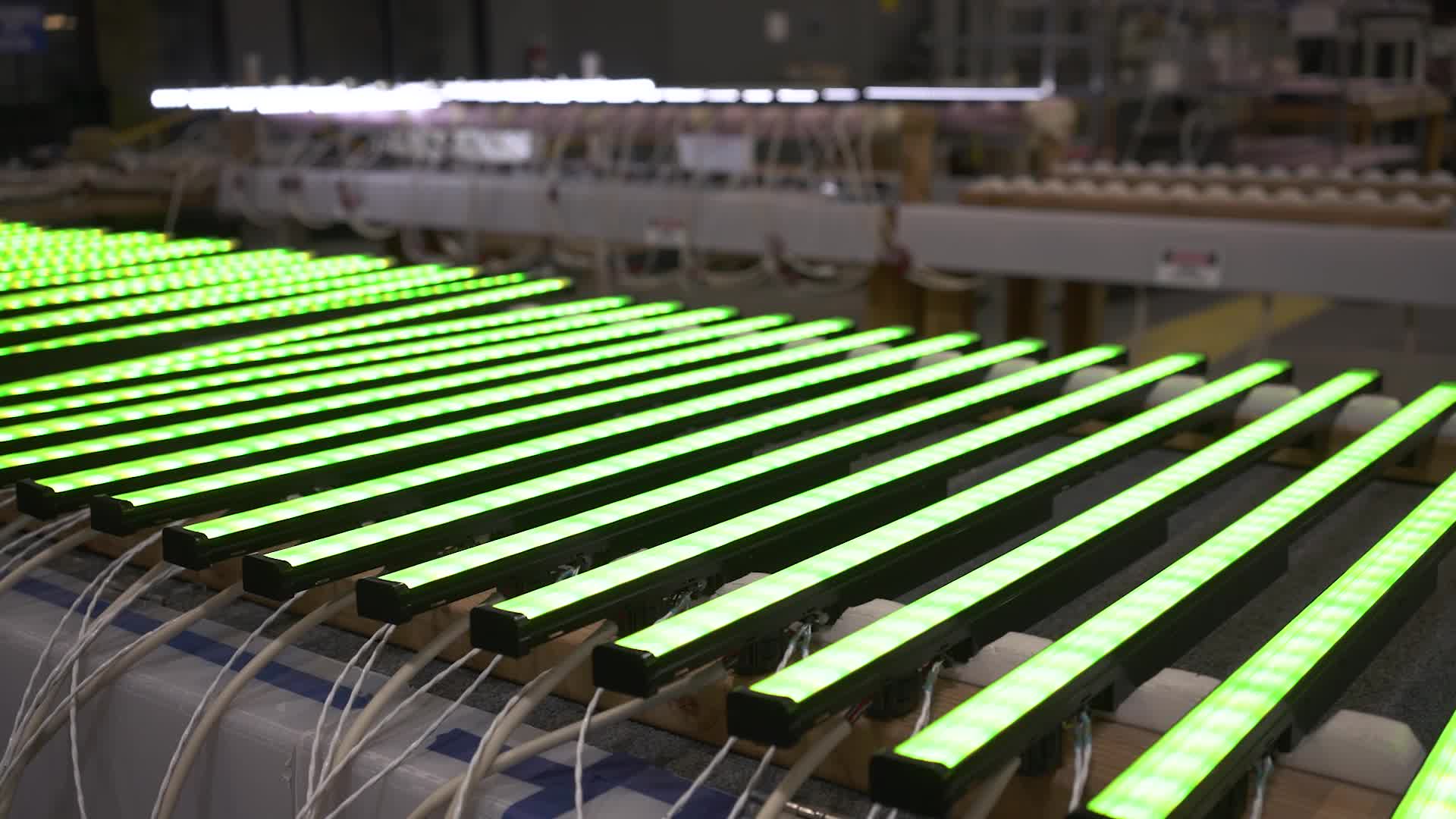

Bruce Aerospace has a proven track record of successfully certifying a wide range of aircraft lighting products. Our expertise spans multiple aircraft platforms, including commercial, military, and business aviation. We have established strong relationships with major aircraft manufacturers and regulatory bodies, ensuring a smooth and efficient certification process.

Our extensive experience in the aerospace industry, combined with our comprehensive certification capabilities, makes us a trusted partner for aircraft manufacturers and operators worldwide.

Certification Support

Our certification process is designed to streamline the approval and installation of our products on various aircraft platforms. We provide full support throughout the certification journey, including:

Engineering Expertise

Our team of skilled engineers provides detailed documentation and technical support to facilitate the certification process. We ensure that all necessary design and performance criteria are met.

DAR/DER Assistance

Our Designated Airworthiness Representatives (DARs) and Designated Engineering Representatives (DERs) work closely with regulatory authorities to obtain the required certifications. Their expertise ensures compliance with all relevant standards and regulations.

Regulatory Compliance

We adhere to stringent regulatory requirements, including FAA, EASA, and other international standards. Our products undergo rigorous testing to ensure they meet all safety and performance criteria.

To support our certification efforts, Bruce Aerospace maintains state-of-the-art testing facilities equipped to perform a wide range of tests, including:

- Environmental Testing: We conduct thorough environmental testing to ensure our products can withstand the harsh conditions of aerospace environments, including temperature extremes, humidity, and altitude.

- Functional Testing: We perform extensive functional testing to verify that our products operate correctly and reliably in real-world conditions.

- RFI/EMI Testing: Our facilities are equipped to conduct Radio Frequency Interference (RFI) and Electromagnetic Interference (EMI) testing, ensuring our products do not interfere with other electronic systems on the aircraft.

- Preliminary DO-160 Testing: We align our testing capabilities with RTCA DO-160 standards, covering a comprehensive range of environmental conditions and test procedures for airborne equipment.